Drinker corrosion: What causes it and how to monitor.

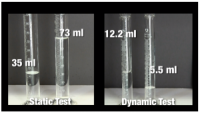

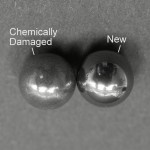

Corrosion of drinker components can be an expensive problem for poultry operations. It pays to monitor for signs of drinker corrosion, particularly if aggressive sanitation programs have been implemented where above normal amounts of chlorine and/or acidifiers are being used…